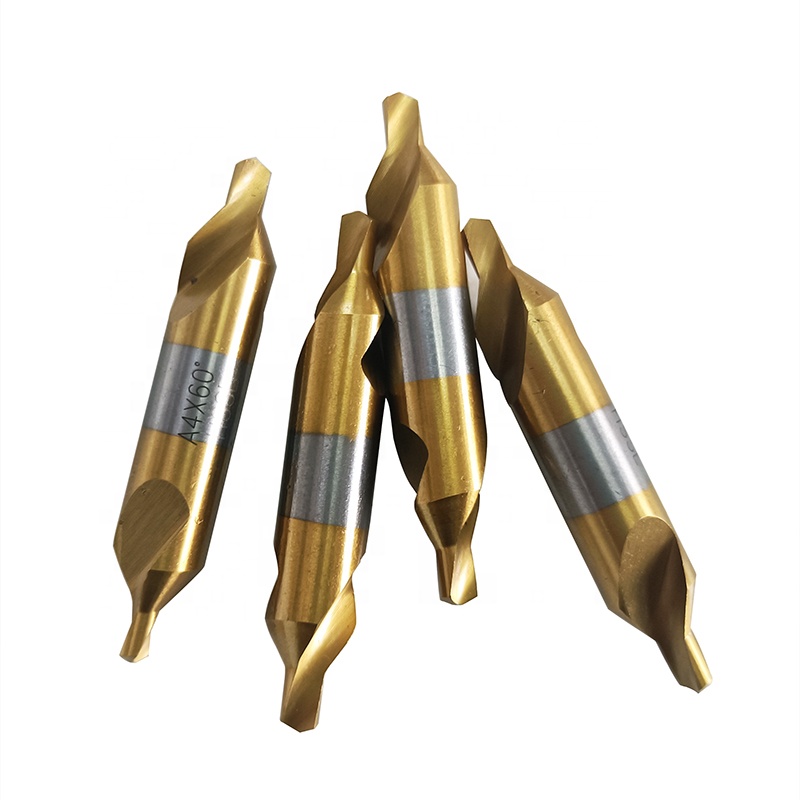

Obere dayameta HSS eriri eriri eriri

Nkọwa ngwaahịa

Emepụtara site na ọkwa dị elu High Speed Cobalt(HSS) maka ịba ụba ike na ike siri ike, ike ihu dị mma na ndụ ngwa ọrụ dị ogologo.

Uru

1. Tungsten ígwè ihe onwunwe, họrọ akwa tungsten ígwè ogwe, na ultra-elu eyi nguzogide na elu siri ike.

2. Extrusion mgbata imewe, ultra-mma urughuru elu okpomọkụ na-eguzogide mkpuchi, dịkwuo anwụ ngwa ngwa

3. Ngwọta na-egweri n'ụzọ zuru ezu, ọmarịcha ebe a na-egweri spiral groove, nhazi spiral kachasị mma, iwepụ mgbawa dị nro na-enweghị ịrapara na mma, na-eme ka arụmọrụ ọrụ dịkwuo mma.

Ndụmọdụ

1. N'ụzọ kwesịrị ekwesị belata ịcha ọsọ na ọnụego nri, nke nwere ike ịgbatị ndụ ọrụ nke onye na-egwe ọka.

2. Mgbe ị na-arụ ọrụ, ọ dị mkpa ịgbakwunye mmiri na-egbutu iji chebe ọnụ mma ahụ, nke mere na ịkpụ ahụ dị nro

3. Ogologo ogologo oge nke ngwá ọrụ na-esi na chuck pụta, ka mma. Ọ bụrụ na ogologo protruding dị ogologo, biko belata ọsọ ma ọ bụ ọnụego nri n'onwe gị

| Aha ngwaahịa | Obere dayameta Spiral Flute carbide skru threading taps | Ngwa ọdabara | Titanium alloy, igwe anaghị agba nchara, magnesium alloy, anwụ-nkedo aluminum | |||

| Ụdị | XINFA | Mkpuchi | Ee | |||

| Ihe onwunwe | HSS | Jiri akụrụngwa | lathe | |||

| L | 1 | Dn | In | D | K | lk |

| 30 | 3.5 | 1.1 | 7 | 3.0 | 2.5 | 5 |

| 32 | 3.5 | 1.3 | 7 | 3.0 | 2.5 | 5 |

| 34 | 4.2 | 1.5 | 8 | 3.0 | 2.5 | 5 |

| 36 | 4.9 | 1.7 | 9 | 3.0 | 2.5 | 5 |

| 36 | 4.9 | 1.8 | 9 | 3.0 | 2.5 | 5 |

| 36 | 4.9 | 1.9 | 9 | 3.0 | 2.5 | 5 |

| 40 | 5.6 | 2.1 | 10 | 3.0 | 2.5 | 5 |

| 42 | 6.3 | 2.3 | 10 | 3.0 | 2.5 | 5 |

| 42 | 5.6 | 2.4 | 10 | 3.0 | 2.5 | 5 |

| 44 | 6.3 | 2.6 | 11 | 3.0 | 2.5 | 5 |

| 44 | 6.3 | 2.7 | 11 | 3.0 | 2.5 | 5 |

Uru ndị ahịa

1. Ịrụ ọrụ dị elu na mmepụta ihe dị iche iche.

2. Chamfer ụdị C nwere ike iji ma site na oghere kpuru.

3. Ịrụ eriri na-enweghị mgbawa na-emepụta eriri siri ike karịa ịkpụ taps na ụbara ibu ibu. Ya mere, a na-atụ aro ka ọ dị elu ịkpụ ọsọ ọsọ.

4. Greater ziri ezi nke okokụre eri na ala elu roughness.

5. Ukwuu kwụsiri ike imewe pụtara obere ihe ize ndụ nke mgbata breakage na kacha usoro nche.

6. Oil uzo nhọrọ mmemme coolant eruba na machining ebe, n'ihu na-amụba ngwá ọrụ ndụ.

Jiri

A na-eji ya n'ọtụtụ ebe

Nrụpụta ụgbọ elu

Igwe mmepụta ihe

Onye na-emepụta ụgbọ ala

Ime ebu

Nrụpụta ọkụ eletrik

Nhazi lathe

Q1: Enwere m ike ịnweta sample maka ule?

A: Ee, anyị nwere ike ịkwado sample. A ga-ana ihe nlele ahụ n'ụzọ ziri ezi dịka mkparita ụka dị n'etiti anyị si dị.

Q2: Enwere m ike itinye akara m na igbe / katọn?

A: Ee, OEM na ODM dị n'aka anyị.

Q3: Gịnị bụ uru nke ịbụ onye nkesa?

A: Nchekwa ahịa mbelata ego pụrụ iche.

Q4: Olee otú ị ga-esi chịkwaa àgwà nke ngwaahịa?

A: Ee, anyị nwere ndị injinia dị njikere inyere ndị ahịa aka na nsogbu nkwado teknụzụ, nsogbu ọ bụla nwere ike ibilite n'oge ntinye okwu ma ọ bụ nrụnye, yana nkwado azụ ahịa. 100% nyocha onwe onye tupu mbukota.

Q5: Enwere m ike ịga leta ụlọ ọrụ gị tupu iwu ahụ?

A: N'ezie, nabata gị nleta nke factory.